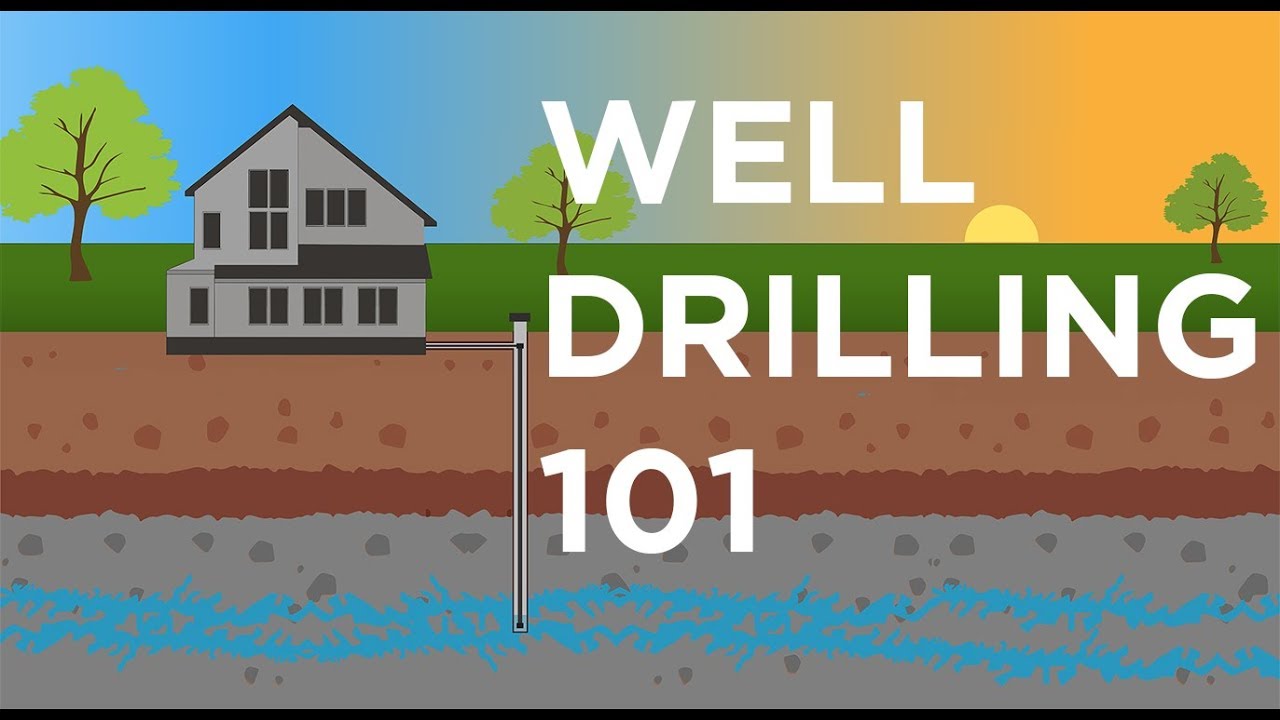

Drilling for a water well might seem simple, but it’s much more complicated than just poking a hole in the ground. Drilling requires careful planning to ensure safety, cost-effectiveness, and efficiency.

The final intermediate casing string is run and cemented. It will put the environmentally sensitive aquifers behind pipes and protect them from drilling and production activities. Wireline logs may be run at this time if desired.

Preparation

Before drilling begins, it is essential to clear out bushes, flower beds, gardens, and trees that could be affected by the drilling equipment. It will also allow a clear path for transporting the equipment to and from the site.

After the soil has been cleared, an OK pad is built. Next, a steel casing is set in 20-foot increments until bedrock is reached. It is a critical step as it helps to prevent the water aquifer from becoming polluted by surface water.

Water and cutting discharge are expected to emerge from the sound hole during the well drilling. The water is pumped in to keep the drill rod lubricated and cooled while the cutting discharge (rock, clay, dirt, low-gravity solids, mud-weighting materials, mud rings, and salt accumulations) is pushed out of the hole. It takes phenomenal technology to keep the hole drilling in a constant 10-foot interval for miles and miles, but this allows wells to access oil and natural gas from deeper underground locations.

Drilling

Drilling can start after your permissions are obtained, and the site is ready. To lubricate and cool the drill bit as it penetrates the Earth, well drilling companies will arrive with a dual rotary drill rig and a support truck filled with water. Your well driller must be qualified and certified to guarantee a high-quality well. They should also know your state’s laws and regulations regarding where your well can be drilled. For example, your well should be located away from potential contaminants, such as animal feedlots, buried fuel tanks, waste disposal, and septic systems, which can pollute groundwater.

Once the well is drilled, it is cased with steel casing. It prevents the well from collapsing and provides a sanitary seal to remove contaminants. The space between the container and the drill hole is filled with a cement slurry. Depending on the well type, engineers will plan the drilling program to include the selection of rigs, their sizes and diameters, expected pressures and temperatures, and the configuration and length of the pipe string.

Installation

Once the prep work is done, the proper permits are obtained, an optimal spot is selected for good drilling, and a licensed driller is brought on site. It’s time to get to work!

While the crew is drilling your well, they will also install a piece of pipe called casing. The casing is installed in 20-foot increments and is put in place to keep the overburden from seeping into your water supply and contaminating it. The casing will extend a few feet above the ground, which helps to ensure surface water and debris aren’t also entering your well from above.

As the drilling continues, the crew will change the drill bit periodically. This process is called tripping and can take anywhere from a day to a week or more. The new bit will then be set, and the rig is lowered down the borehole. As the drill string is lowered into the casing, the weight indicator is monitored to ensure a formation is not restricting the wireline.

Testing

Once your well is drilled, your crew will test it for proper water yield. It ensures that your well will meet all your household and property water needs.

After the test, your contractor will put a bentonite surface seal on the first 18 feet of the well casing. It is to protect the well from contamination from the surrounding overburden.

The drilling process takes place with a large rig that requires plenty of space and access to your land. A site assessment ensures the location is suitable for the well and any necessary permits are obtained.

The drilling crew will bore through the overburden (a combination of dirt, rock, clay, and other material that sits above a viable aquifer) in 20-foot increments. It may take some time, but it is crucial to ensure that a high-quality aquifer is reached. A wireline formation tester is run throughout this phase to provide data about the reservoir interval lithologies and fluids. This data calculates skin and absolute open flow (AOF).

Leave a Reply